This series of products features a high-performance, intelligent integrated control valve assembly specifically designed for dual-pump hydraulic systems. It deeply integrates the output power of two hydraulic pumps (such as a main pump + auxiliary pump, or a tandem pump), achieving coordinated management, on-demand allocation, and efficient utilization of system flow and pressure through advanced merging, splitting, and priority control logic.

The DPV series goes beyond simple pipe connections. It integrates advanced technologies such as load sensitivity, pressure compensation, and electro-hydraulic proportional control, intelligently adjusting the power output and merging timing of the two pumps according to the needs of different equipment operating modes (such as driving, combined operation, and precise control). It serves as a core hydraulic control platform for improving the operating efficiency, fuel economy, control precision, and system reliability of complex equipment such as large construction machinery, high-end agricultural equipment, and special-purpose vehicles.

Core Advantages

Dual-Power Intelligent Collaboration: Intelligent control of the merging and splitting of the main and auxiliary pumps. When high flow rates are required (e.g., rapid boom lifting), the two pumps merge to provide powerful output; during precise operations or single actions, they split or unload, significantly reducing energy consumption and heat generation, achieving overall energy savings of 15%-25%.

On-Demand Allocation, Doubling Efficiency: Through load-sensitive (LS) or electro-hydraulic proportional control, the flow and pressure output from the two pumps are precisely and preferentially allocated to the actuators with the most urgent needs (e.g., steering, working devices), eliminating motion lag and improving the coordination of complex actions and overall operational efficiency.

High-Pressure, High-Flow Platform: Utilizing a large-diameter flow channel design (e.g., NG16, NG25), it can handle total combined flow rates of up to 500-1000 L/min, with operating pressures covering 31.5-42 MPa, providing a stable and reliable high-pressure, high-flow power source for heavy equipment.

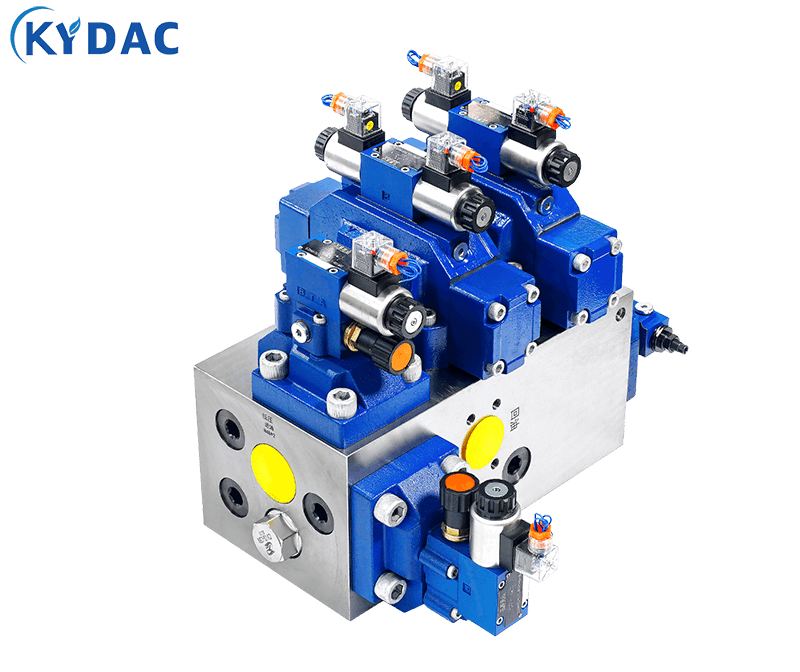

Highly integrated, simplifying the system: Complex dual-pump control logic, main safety valve, check valve, and logic valves are highly integrated into one or two compact valve blocks, greatly simplifying the bulky and complex piping connections of traditional dual-pump systems, reducing leakage points, and improving system rigidity and reliability.

For intelligent and automated systems: Provides standard hydraulic pilot or advanced electro-hydraulic proportional control interfaces, enabling seamless communication with the equipment’s main controller (ECU/PLC). This allows for easy implementation of advanced functions such as operating mode switching, power limit adjustment, and fault diagnosis, forming a key hydraulic foundation for equipment intelligence.