A custom-designed, high-performance, and highly reliable integrated hydraulic valve system. This system deeply understands the stringent challenges faced by alligator shears when shearing various types of scrap steel (profiles, automotive bodies, industrial waste), including extreme impact loads, highly polluting environments, and high-intensity continuous operation.

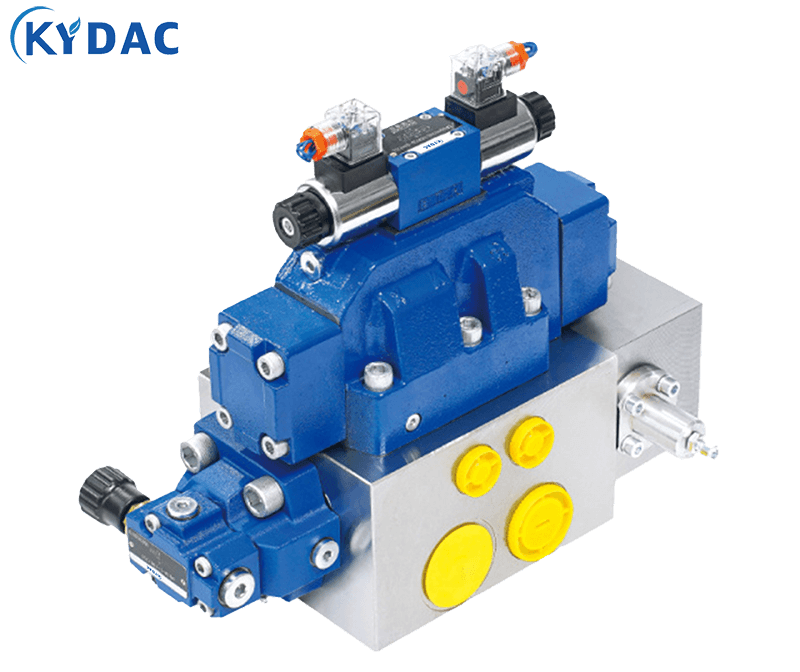

We don’t simply offer a collection of standard valves; instead, we highly integrate core and auxiliary functions such as main shear cylinder drive, feeder control, side thrust device coordination, and intelligent system pressure and flow management into one or more optimized and robust valve blocks. The CUT series aims to become the core hydraulic guarantee for improving the shearing force, operating efficiency, service life, and overall economic benefits of your shearing equipment through superior impact resistance, precise timing control, extremely high energy efficiency, and convenient maintenance.

Core Advantages and Value

Reinforced Design for Impact Loads:** The internal flow channels and core components of the valve assembly (such as the main relief valve) feature a special reinforced and buffered design, capable of absorbing and smoothing the massive hydraulic shock generated during shearing. This effectively protects the pump, pipelines, and the entire hydraulic system, significantly reducing the failure rate and extending equipment life.

Intelligent and Efficient Power Management:** Optional load-sensitive (LS) or constant power (CP) control systems are available. Flow and pressure are automatically reduced during idle or light load periods, while maximum power is provided during shearing, achieving “on-demand power supply.” This significantly reduces energy consumption and system heat generation, achieving energy savings of 15%-30%.

Precise and Reliable Timing Control:** Complex action logic such as “pressing down the pressure bar → advancing the main shear cylinder → shearing completion → rapid retraction of the main cylinder → lifting the pressure bar” is highly integrated through hydraulic or electro-hydraulic control, ensuring smooth, precise, and interference-free operation, improving shearing cycle time and operational safety.

Unfazed by Harsh Working Conditions:** Heavy-duty filtration design improves the system’s contamination tolerance. Seals are made of wear-resistant and tear-resistant materials. The valve body boasts a robust structure and excellent shock resistance, specifically designed for factory environments with high metal shavings and vibration.

Highly integrated for easy maintenance: The functions of multiple distributed valves are integrated into a few valve blocks, greatly simplifying complex external piping and reducing potential leak points. Utilizing cartridge valve technology and a modular design, key control units can be replaced independently and quickly, and a clear diagnostic interface significantly reduces troubleshooting and repair time.