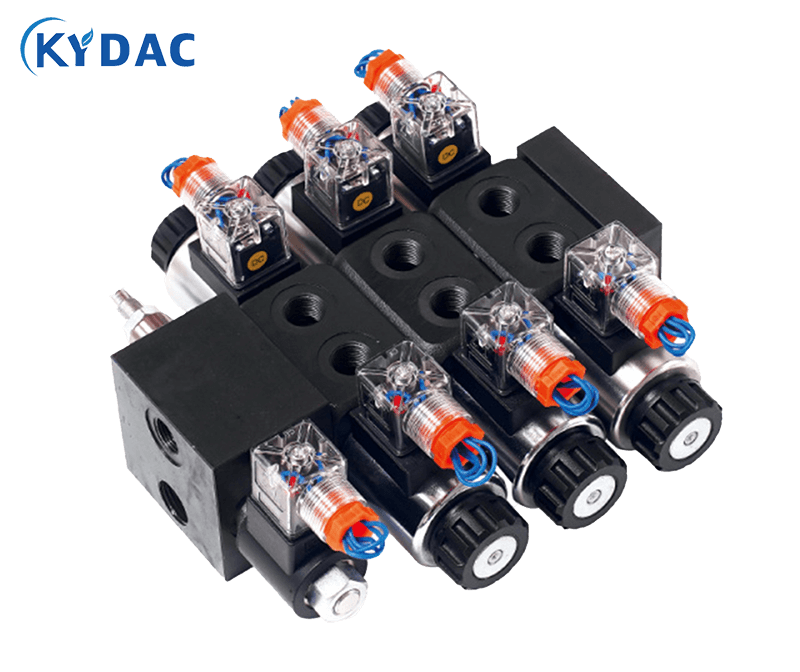

The KYDAC EMC series electromagnetic multi-way directional control valve is an integrated hydraulic core component designed for centralized electrical control of multiple actuators. This series highly integrates multiple independent electromagnetic directional control units into a compact valve body. By receiving electrical signals from a controller (such as a PLC), it enables centralized, precise, and automated control of the working direction of multiple hydraulic cylinders or motors.

It perfectly solves the problems of complex piping, large installation space, and low reliability associated with traditional decentralized control systems, making it an ideal choice for engineering machinery automation, centralized production line control, and functional integration in special vehicles. We offer a variety of configurations from standard 2-way to high-density 12-way, and support modular customization of pressure, flow rate, and additional functions, aiming to create the simplest, most reliable, and most intelligent “hydraulic nerve center” for your equipment.

Core Advantages

High Integration, Space and Cost Savings:** Integrating multiple solenoid valve functions into one unit greatly simplifies external piping connections, reduces leakage points, saves over 50% of installation space, and significantly reduces system procurement and assembly costs.

Electrically Controlled Drive, Precise and Efficient:** Standard configuration features DC 24V or AC 220V solenoid drive, with rapid response (switching time <100ms). It seamlessly interfaces with various industrial controllers, easily achieving remote control, automated sequential operation, and interlock protection.

Modular Design, Flexible Customization:** Utilizing a monoblock or sectional structure, it can be flexibly combined according to your specific needs (such as number of channels, intermediate functions, pressure settings, additional overflow or oil replenishment functions) to achieve a “tailor-made” configuration.

Rugged and Reliable, Adaptable to Harsh Environments:** The valve body is made of high-strength cast iron or aluminum alloy, and key seals are oil and temperature resistant. With an IP65 protection rating, it has excellent vibration resistance, shock resistance, and dust and water resistance, making it suitable for harsh working conditions such as construction machinery and agricultural equipment.

Easy maintenance and high versatility: Standardized electrical and hydraulic interfaces, and a versatile electromagnet coil allow for quick and easy replacement. Clear port markings and a compact structure simplify daily inspection and maintenance.