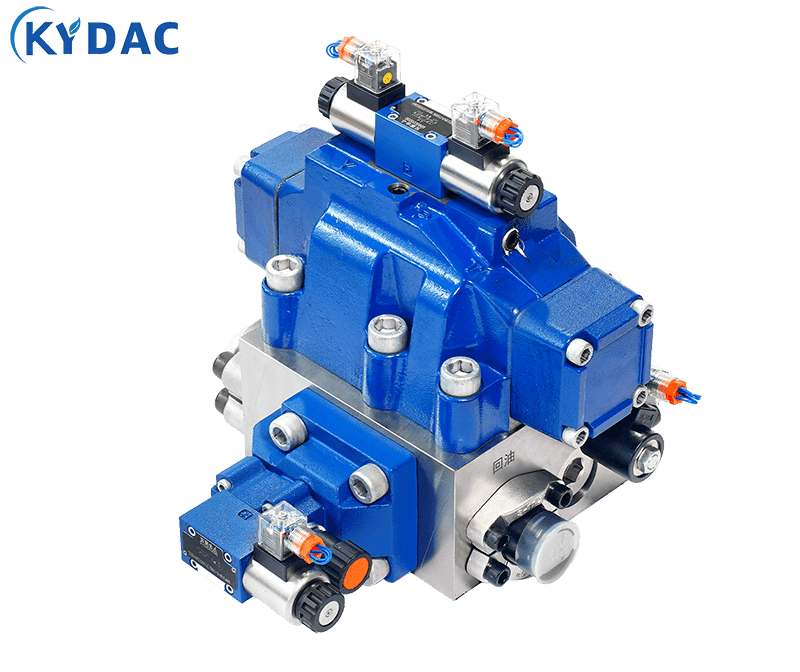

This innovative, specialized hydraulic valve assembly deeply integrates electromagnetic reversing with active drain/pressure relief functionality. This series is specifically designed for applications requiring remote, rapid, and controllable venting of hydraulic actuators (cylinders, motors) or the main system circuit during equipment shutdown, maintenance, safety locking, or specific process flows.

Compared to traditional manual ball valves or decentralized pressure relief solutions, the EDR series achieves precise switching and active venting of the hydraulic circuit with a single electrical signal. This significantly improves operational safety and convenience, and provides a crucial hydraulic interface for automated equipment management, energy conservation, environmental protection, and preventative maintenance. It is the ideal choice for aerial work platforms, large hydraulic presses, construction machinery, sanitation vehicles, and various industrial equipment requiring periodic venting or emergency pressure relief.

Key Advantages

One-Button Remote Control: Integrating a high-performance DC/AC electromagnet, commands can be sent via button, PLC, or remote control to remotely initiate the oil draining process within seconds, completely eliminating the tediousness and danger of climbing equipment and operating manual valves.

Intrinsically Safe, Preventing Misoperation: The oil draining function only activates upon receiving a clear electrical signal command, fundamentally avoiding the risk of manual pressure relief due to accidental contact or negligence. This provides reliable assurance for equipment lockout/tagout procedures and maintenance safety.

Highly Efficient and Rapid Drainage: Optimized internal flow channels and a direct-acting valve core design provide a large-diameter, low-resistance draining path, quickly draining oil from the target oil chamber back to the tank, significantly shortening equipment preparation or maintenance time and improving work efficiency.

System Integration, Simple and Reliable: Directional control and oil draining functions are modularly integrated into a compact valve block, reducing external piping, joints, and potential leakage points. Robust structure, reliable sealing, and strong resistance to contamination.

Flexible and versatile configuration: It can be customized to meet specific needs, providing various control logics such as normally closed (powered to drain oil) or normally open (powered to shut off). It can be integrated with check valves, throttle valves, etc., to achieve a smooth and controllable discharge rate.