Core Product Advantages

Industry-Leading Flow Rate: 100 L/min nominal flow, delivering unmatched hydraulic power for ultra-heavy-duty equipment.

Extreme Pressure Capacity: 350 bar maximum working pressure ensures superior stability and reliability under extreme load conditions.

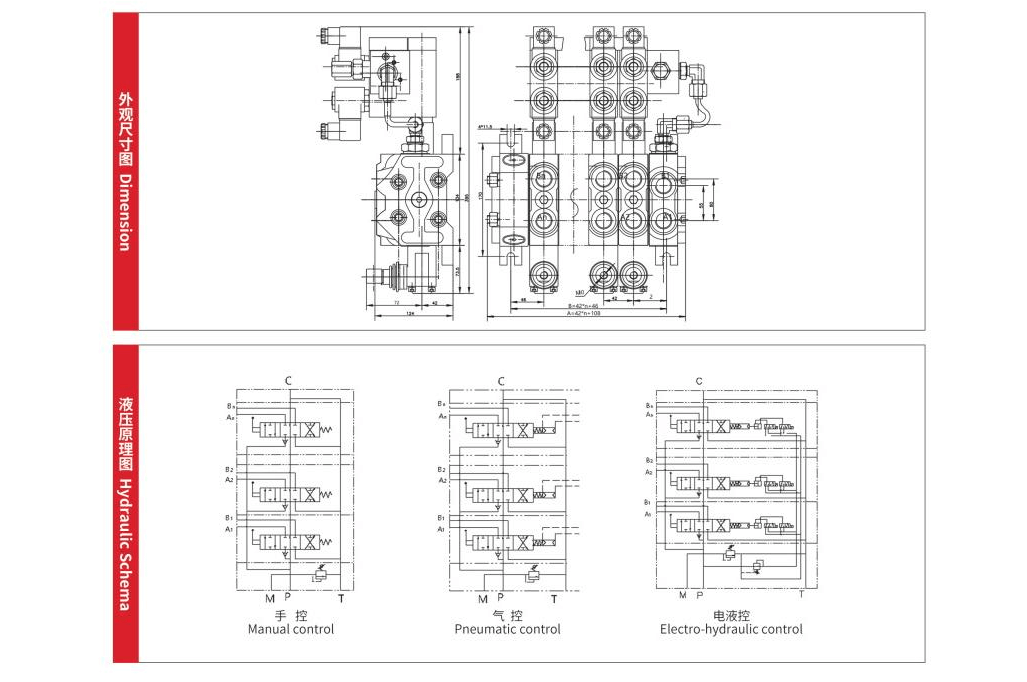

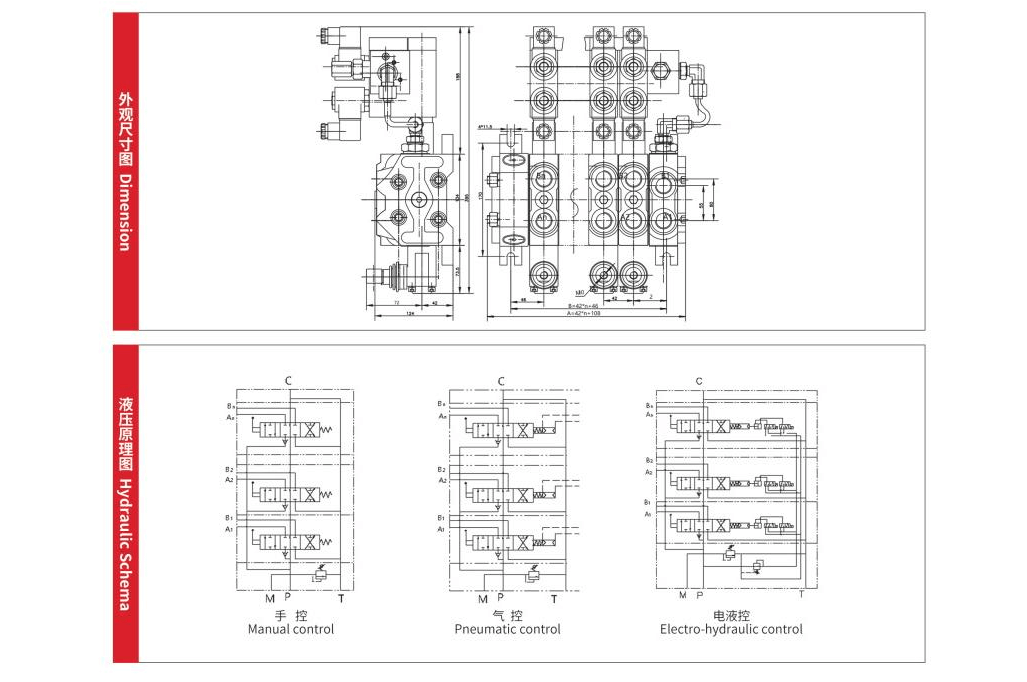

Ultimate Configuration Flexibility: Sectional structure supports modular combination and expansion of 1~12 sections, the ultimate solution for building highly complex hydraulic control systems.

Global & Harsh Environment Suitability: Withstands extreme ambient temperatures from -40℃ to 80℃ and is compatible with a wide fluid viscosity range of 12-400 cSt, confidently handling any demanding operating environment worldwide.

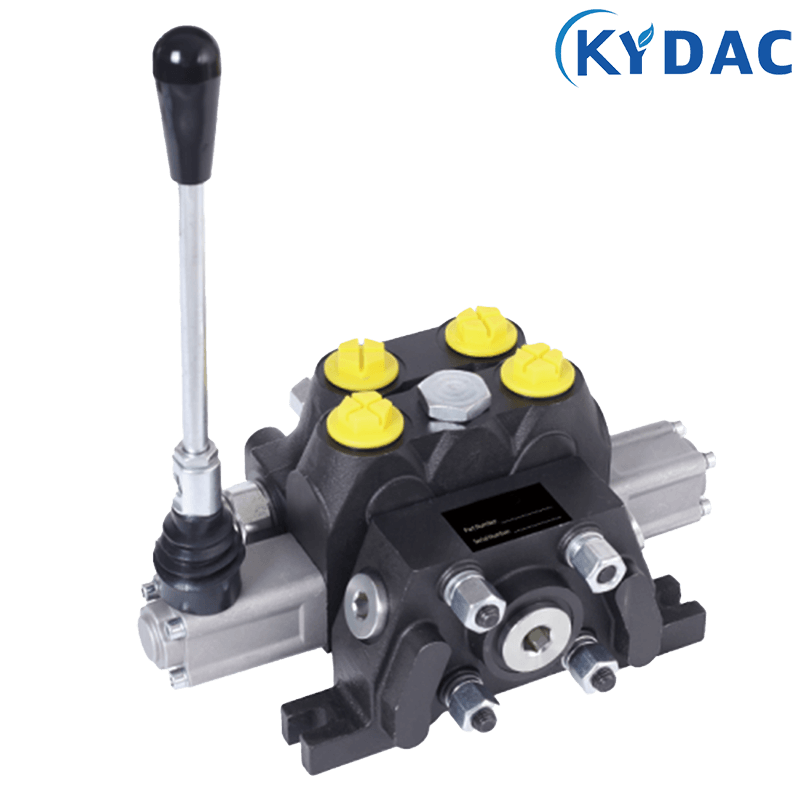

Robust & Long-Lasting: High-strength cast iron body, reliable classic sectional design, easy maintenance, committed to achieving the lowest total cost of ownership over the equipment’s full lifecycle.

Product Overview

The KYDAC DCV100 Series is a high-flow sectional multi-way directional control valve that sets the industry benchmark. This product is specifically designed to meet the extreme demands for hydraulic power and control complexity from ultra-heavy-duty construction machinery, high-end drilling equipment, and large-scale industrial sanitation systems.

It integrates an impressive 100 L/min high flow rate with stable 350 bar ultra-high working pressure, combined with a highly flexible 1-to-12-section modular design. Serving as the centralized, efficient, reliable, and fully customizable “hydraulic control center” for top-tier equipment requiring coordinated control of dozens of actuators (cylinders, motors), the DCV100 is not only a leader in performance specifications but also a core cornerstone for helping customer equipment break productivity boundaries and achieve operational excellence.

Detailed Technical Specifications

In-Depth Features & Advantages

Powerful Performance, Redefining Efficiency Benchmarks

The 100 L/min ultra-high flow provided by the DCV100 can simultaneously meet the massive hydraulic fluid demand of multiple large-displacement actuators, significantly shortening the cycle times of cylinders or driving higher RPM hydraulic motors. In synergy with 350 bar high pressure, it provides dual assurance of “power” and “speed” for heavy equipment, enabling revolutionary improvements in production efficiency for operations such as large-scale mining excavation, rapid continuous lifting, and efficient deep-sea drilling.

Infinite Combinations, Mastering System Complexity

The sectional structure is an intelligent design to meet the demands of control. Users can freely select and sequence the required functional valve sections (up to 12) like building blocks, based on the host equipment’s precise functional list (e.g., all main/auxiliary hoisting, luffing, telescoping, slewing, super-lift, and control of up to 10 outriggers for an all-terrain crane). This provides OEMs with unprecedented design freedom, perfectly realizing all current functions while also reserving seamless interfaces for future product line upgrades.

Tailored for World-Class Heavy-Duty Equipment

Ultra-Large Construction Machinery: An ideal control core for the main hydraulic systems of “national heavy-duty equipment” such as 400-ton+ giant hydraulic excavators, 1000-ton all-terrain cranes, and large mining dump trucks.

High-End Energy & Drilling Equipment: Meets the stringent requirements of ultra-deep-hole scientific drill rigs, large oil & gas drilling platforms, and Full-Face Tunnel Boring Machines (TBMs) for ultra-high, stable flow supply and numerous independent, precise control circuits.

Industrial Sanitation & Special Operation Systems: Suitable for complex, highly integrated, and automated hydraulic systems in large waste resource recovery centers, municipal tunnel comprehensive maintenance vehicles, etc.

Reliable, Durable & Easy to Maintain

Despite the sectional design, through precision-machined hardened mating surfaces, high-performance sealing components, and scientific bolt pre-tensioning technology, the DCV100 ensures the sealing integrity and structural rigidity of the entire valve stack under long-term high-pressure shock. Its modular nature makes maintenance extremely convenient—inspection or replacement of any single valve section does not require disassembling the entire large stack, greatly reducing maintenance difficulty, time, and cost, ensuring high equipment availability.

Typical Application Scenarios

1000-Ton All-Terrain Crane: Serves as the “nerve center” of the machine’s entire hydraulic system, integrating and precisely coordinating over 20 complex movements including all hoisting, luffing, telescoping, slewing, and outrigger operations, ensuring and safety in lifting operations.

Ultra-Large Mining Hydraulic Excavator: Provides power for the massive work equipment (boom, arm, bucket) while simultaneously and efficiently controlling auxiliary systems like travel, swing, dust suppression, and automatic lubrication, meeting the stringent demands of 24/7 continuous, efficient mining operations.

Deepwater Drilling Platform Hydraulic Power Unit: Provides stable, reliable, high-flow, high-pressure hydraulic power for critical equipment such as riser tensioner systems, blowout preventer (BOP) stacks, and remotely operated vehicles (ROVs), serving as core equipment for ensuring safe deep-sea energy extraction.

Quality & Service Commitment

KYDAC adheres to the manufacturing philosophy that “performance stems from standards.” Every DCV100 system starts with in-depth communication with the customer, goes through precision modular manufacturing, individual section performance testing, complete stack testing, and simulated operating condition high-pressure endurance testing. We deliver not just a set of valves, but a deeply customized, reliably performing, and fully supported hydraulic system solution.

Begin Your Top-Tier Equipment Hydraulic Upgrade Journey

When your equipment stands at the pinnacle of its industry, every performance improvement signifies tremendous value. The KYDAC DCV100 Series is born precisely to help top-tier equipment manufacturers limits and define the future.

Contact our senior application engineers now to start a conversation about peak performance, extreme reliability, and infinite possibilities. Let’s build the powerful “hydraulic heart” for your next-generation flagship equipment.