Core Product Advantages

Industry-Leading Ultra-High Flow Rate: 140 L/min nominal flow, meeting the top-tier demand for hydraulic power in ultra-heavy-duty equipment.

Extreme High-Pressure Stability: 350 bar maximum working pressure ensures robust performance and lasting reliability under extreme operating conditions.

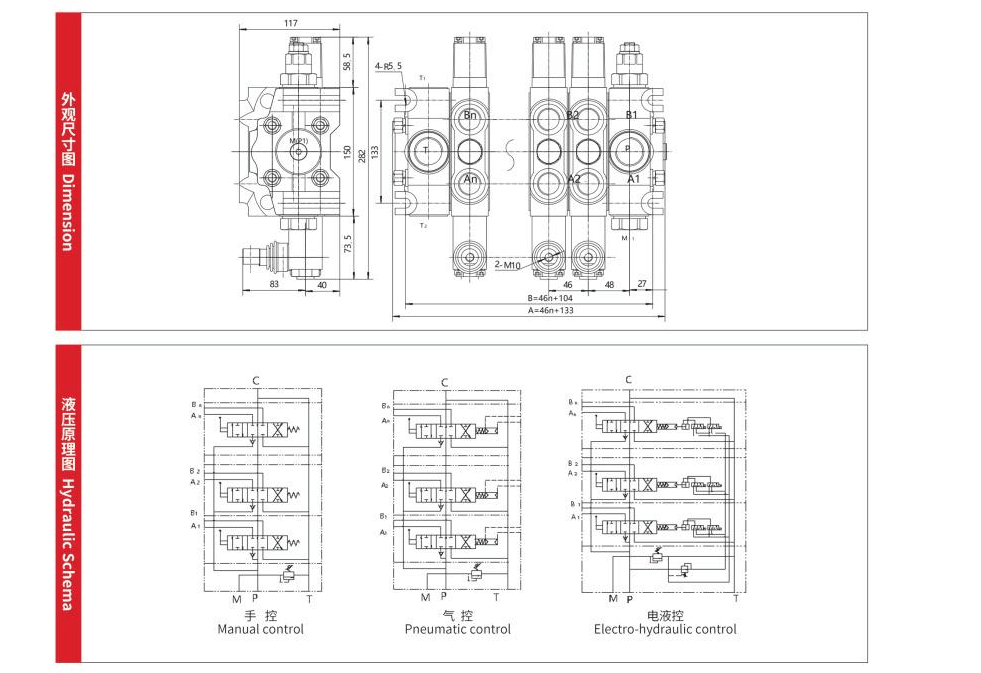

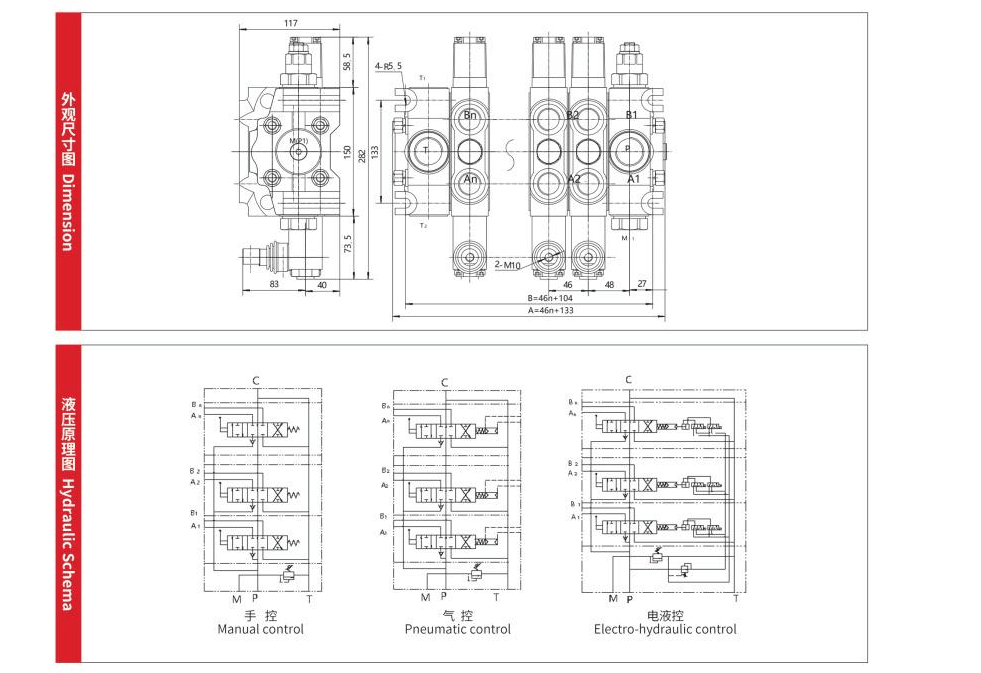

Modular Infinite Expandability: Sectional structure supporting flexible configuration of 1~12 functional sections, serving as the ideal foundation for building the most complex hydraulic systems.

Global & Harsh Environment Adaptability: Operating temperature range from -40℃ to 80℃, compatible with fluid viscosities from 12-400 cSt, confidently handling various extreme working environments worldwide.

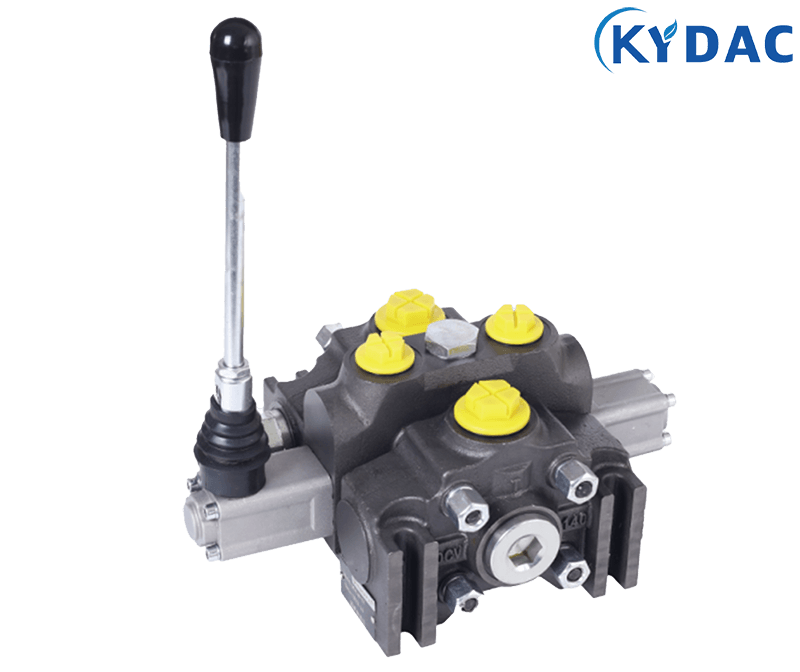

Industrial-Grade Robustness & Durability: High-strength cast iron body, modular design for ease of maintenance, dedicated to achieving maximum lifetime value and minimum maintenance costs.

Product Overview

The KYDAC DCV140 Series is a premium hydraulic control solution engineered for the future of ultra-heavy-duty machinery. This product combines澎湃 flow of 140 L/min with sustained ultra-high working pressure of 350 bar, representing the pinnacle of high-flow hydraulic control technology.

Designed specifically for areas demanding exceptionally high hydraulic power and system complexity, such as extra-large mining machinery, giant construction equipment, and deep-sea drilling platforms, the DCV140 delivers unmatched instantaneous power output. Furthermore, through its highly modular sectional structure, it enables centralized, coordinated, and intelligent control of dozens of actuators. It is the “core brain” for building efficient, reliable, and customizable top-tier hydraulic systems.

Detailed Technical Specifications

In-Depth Features & Advantages Analysis

Powerful Performance, Redefining Operational Efficiency

The 140 L/min ultra-high flow rate can simultaneously provide ample hydraulic fluid supply to multiple extra-large cylinders or high-power motors, pushing the work cycle times of heavy equipment to the极限. Combined with stable 350 bar high pressure, it offers an unprecedented combination of “power” and “speed” for operations like extra-large excavation, rapid lifting, powerful pushing, and efficient drilling, directly translating into productivity and operational capability.

Flexible Architecture, Mastering Ultimate Complexity

Utilizing the classic sectional structure, it can be freely configured with up to 12 work sections. This design grants system integrators and OEMs ultimate design freedom. Users can precisely customize the function, type, and quantity of control circuits according to specific project requirements, building hydraulic control systems ranging from simple to complex. This flexibility not only meets all current functional needs but also provides a perfect interface for future technological upgrades and functional expansion.

Engineered for World-Class Flagship Equipment

Extra-Large Mining & Construction Machinery: An ideal choice for driving the core equipment of “mega-projects” such as 800-ton class and above extra-large hydraulic excavators, giant wheel loaders, and large port handling equipment.

High-End Energy & Deep-Sea Equipment: Meets the stringent demands of ultra-deepwater drilling platforms, large offshore wind turbine installation vessels, and Full-Face Tunnel Boring Machines (TBMs) for ultra-high flow supply and super-multi-circuit control.

Special Industrial & Testing Systems: Suitable for special fields requiring and high-precision control, such as large material testing machines, heavy-duty marine steering gear systems, and industrial production lines.

Reliable, Durable, Smart & Easy Maintenance

Through high-precision machined hardened mating surfaces, multi-redundant sealing design, and scientific preload control technology, the DCV140 ensures absolute sealing integrity and structural integrity of the large valve stack under long-term loads. Its modular design makes maintenance extremely efficient—diagnosis, repair, or replacement of any single functional section can be completed independently without affecting the overall system, minimizing downtime and ensuring continuous, efficient equipment operation.

Typical Application Scenarios

Extra-Large Mining Hydraulic Excavator: Serves as the “power center” of the machine’s entire hydraulic system, providing power to the massive boom, arm, and bucket, while simultaneously coordinating dozens of auxiliary systems like travel, swing, dust suppression, and cooling, tackling, high-intensity mining operations.

Full-Face Tunnel Boring Machine (TBM): Integratively controls all key hydraulic functions, including cutterhead drive, thrust system, segment erector, and auxiliary handling, acting as the “heart” component ensuring efficient and safe tunnel excavation.

Large Offshore Construction Vessel (e.g., Wind Turbine Installation Vessel): Provides stable and reliable high-flow, high-pressure hydraulic power for heavy lifting systems, dynamic positioning (DP) systems, leg jacking systems, etc., serving as the core for completing complex offshore lifting and installation operations.

Quality & Service Commitment

KYDAC adheres to the manufacturing philosophy of ” Performance, Originates from Fine Engineering.” Every DCV140 system begins with in-depth technical co-creation with the customer, undergoing processes from raw material selection, precision modular manufacturing, rigorous independent and integration testing, to final validation simulating extreme operating conditions. We deliver not just a product, but a high-performance, deeply compatible, fully supported top-tier hydraulic system partner.

Embark on Your Performance Exploration

When your goal defines new heights for the industry, the required power and control solutions must also. The KYDAC DCV140 Series is precisely crafted to empower such challenges.

Contact our expert team immediately to explore how to integrate this power and control into your next-generation flagship equipment. Let’s work together to performance boundaries and achieve results.