What Is A Solenoid Valve And How Does It Work? market is expanding rapidly.

Time : Jan 15, 2025 View : 1,065

CONSTRUCTION

Solenoid valves are control units which, when electrically energized or de-energized, either shut off or allow fluid flow. The actuator takes the form of an electromagnet. When energized, a magnetic field builds up which pulls a plunger or pivoted armature against the action of a spring. When de-energized, the plunger or pivoted armature is returned to its original position by the spring action.

VALVE OPERATION

According to the mode of actuation, a distinction is made between direct-acting valves, internally piloted valves, and externally piloted valves. A further distinguishing feature is the number of port connections or the number of flow paths (“ways”).

DIRECT-ACTING VALVES

With a direct-acting solenoid valve, the seat seal is attached to the solenoid core. In the de-energized condition, a seat orifice is closed, which opens when the valve is energized

DIRECT-ACTING 2- WAY VALVES

Two-way valves are shut-off valves with one inlet port and one outlet port (Fig. 1). In the de-energized condition, the core spring, assisted by the fluid pressure, holds the valve seal on the valve seat to shut off the flow. When energized, the core and seal are pulled into the solenoid coil and the valve opens. The electro-magnetic force is greater than the combined spring force and the static and dynamic pressure forces of the medium. figure 1

DIRECT-ACTING 3-WAY VALVES

Three-way valves have three port connections and two valve seats. One valve seal always remains open and the other closed in the de-energized mode. When the coil is energized, the mode reverses. The 3-way valve shown in Fig. 2 is designed with a plunger type core. Various valve operations can be obtained according to how the fluid medium is connected to the working ports in Fig. 2. The fluid pressure builds up under the valve seat. With the coil de-energized, a conical spring holds the lower core seal tightly against the valve seat and shuts off the fluid flow. Port A is exhausted through R. When the coil is energized the core is pulled in, the valve seat at Port R is sealed off by the spring-loaded upper core seal. The fluid medium now flows from P to A. figure 2 Unlike the versions with plunger-type cores, pivoted-armature valves have all port connections in the valve body. An isolating diaphragm ensures that the fluid medium does not come into contact with the coil chamber. Pivoted-armature valves can be used to obtain any 3-way valve operation. The basic design principle is shown in Fig. 3. Pivoted-armature valves are provided with manual override as a standard feature. figure 3

INTERNALLY PILOTED SOLENOID VALVES

With direct-acting valves, the static pressure forces increase with increasing orifice diameter which means that the magnetic forces, required to overcome the pressure forces, become correspondingly larger. Internally piloted solenoid valves are therefore employed for switching higher pressures in conjunction with larger orifice sizes; in this case, the differential fluid pressure performs the main work in opening and closing the valve.

INTERNALLY PILOTED 2-WAY VALVES

Internally piloted solenoid valves are fitted with either a 2- or 3-way pilot solenoid valve. A diaphragm or a piston provides the seal for the main valve seat. The operation of such a valve is indicated in Fig. 4. When the pilot valve is closed, the fluid pressure builds up on both sides of the diaphragm via a bleed orifice. As long as there is a pressure differential between the inlet and outlet ports, a shut-off force is available by virtue of the larger effective area on the top of the diaphragm. When the pilot valve is opened, the pressure is relieved from the upper side of the diaphragm. The greater effective net pressure force from below now raises the diaphragm and opens the valve. In general, internally piloted valves require a minimum pressure differential to ensure satisfactory opening and closing. Omega also offers internally piloted valves, designed with a coupled core and diaphragm that operate at zero pressure differential (Fig. 5). figure 4

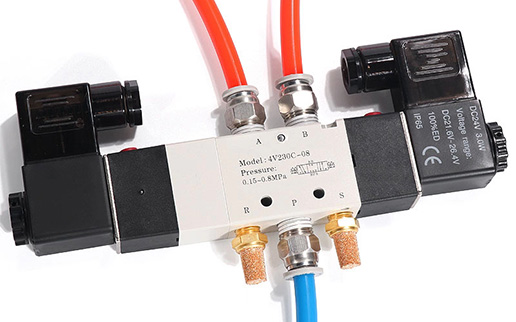

INTERNALLY PILOTED MULTI-WAY SOLENOID VALVES

Internally piloted 4-way solenoid valves are used mainly in hydraulic and pneumatic applications to actuate double-acting cylinders. These valves have four port connections: a pressure inlet P, two cylinder port connections A and B, and one exhaust port connection R. An internally piloted 4/2-way poppet valve is shown in Fig. 6. When de-energized, the pilot valve opens at the connection from the pressure inlet to the pilot channel. Both poppets in the main valve are now pressurized and switch over. Now port connection P is connected to A, and B can exhaust via a second restrictor through R. figure 5

EXTERNALLY PILOTED VALVES

With these types an independent pilot medium is used to actuate the valve. Fig. 7 shows a piston-operated angle-seat valve with closure spring. In the unpressurized condition, the valve seat is closed. A 3-way solenoid valve, which can be mounted on the actuator, controls the independent pilot medium. When the solenoid valve is energized, the piston is raised against the action of the spring and the valve opens. A normally-open valve version can be obtained if the spring is placed on the opposite side of the actuator piston. In these cases, the independent pilot medium is connected to the top of the actuator. Double-acting versions controlled by 4/2-way valves do not contain any spring. figure 6

MATERIALS

All materials used in the construction of the valves are carefully selected according to the varying types of applications. Body material, seal material, and solenoid material are chosen to optimize functional reliability, fluid compatibility, service life and cost.

BODY MATERIALS

Neutral fluid valve bodies are made of brass and bronze. For fluids with high temperatures, e.g., steam, corrosion-resistant steel is available. In addition, polyamide material s used for economic reasons in various plastic valves.

SOLENOID MATERIALS

All parts of the solenoid actuator which come into contact with the fluid are made of austenitic corrosion-resistant steel. In this way, resistance is guaranteed against corrosive attack by neutral or mildly aggressive media.

SEAL MATERIALS

The particular mechanical, thermal and chemical conditions in an application factors in the selection of the seal material. the standard material for neutral fluids at temperatures up to 194°F is normally FKM. For higher temperatures EPDM and PTFE are employed. The PTFE material is universally resistant to practically all fluids of technical interest.

PRESSURE RATINGS – PRESSURE RANGE

All pressure figures quoted in this section represent gauge pressures. Pressure ratings are quoted in PSI. The valves function reliably within the given pressure ranges. Our figures apply for the range 15% undervoltage to 10% overvoltage. If 3/2-way valves are used in a different operation, the permitted pressure range changes. Further details are contained in our data sheets.In the case of vacuum operation, care has to be taken to ensure that the vacuum is on the outlet side (A or B) while the higher pressure, i.e. atmospheric pressure, is connected to the inlet side (P). In this case, the valve must be designed for vacuum operation. The minimum pressure differential must be observed.

FLOW RATE VALUES

Flow rate values are quoted in GPM. The flow rate is the volume of fluid that passes through the valve per unit of time. The flow rate is dependent on the orifice size, the pressure differential across the valve, and the viscosity of the fluid.

SOLENOID ACTUATOR

The solenoid actuator is the electrical part of the valve that converts electrical energy into mechanical energy. The solenoid actuator consists of a coil, a core, and a spring. When the coil is energized, a magnetic field is created that pulls the core into the coil, which in turn opens or closes the valve.

COILS

Coils are made of copper wire and are wound around a bobbin. The number of turns in the coil determines the strength of the magnetic field. The coil is encapsulated in a protective housing to prevent damage from moisture and other environmental factors.

THERMAL EFFECTS

Thermal effects can affect the performance of solenoid valves. The temperature of the coil can increase due to the flow of current, which can lead to a decrease in the magnetic force. This can cause the valve to malfunction. To prevent this, some solenoid valves are designed with heat sinks or other cooling mechanisms.

TIME DEFINITIONS (VDE0580) RESPONSE TIMES

Response times are the time it takes for the valve to open or close after the coil is energized or de-energized. Response times are important for applications that require precise control of fluid flow. Response times are typically measured in milliseconds.

ON PERIOD

On period is the time that the coil is energized. The on period can affect the temperature of the coil and the life of the valve.

CYCLE PERIOD

Cycle period is the total time for one complete cycle of the valve, including the on period and the off period.

RELATIVE DUTY CYCLE

Relative duty cycle is the ratio of the on period to the cycle period. The relative duty cycle is an important factor in determining the life of the valve.

VALVE OPERATION

Valve operation can be affected by the type of fluid, the temperature of the fluid, and the pressure of the fluid. It is important to select a valve that is compatible with the fluid and the operating conditions.

VISCOSITY

Viscosity is a measure of the fluid’s resistance to flow. Viscosity can affect the flow rate through the valve and the pressure drop across the valve. It is important to select a valve that is suitable for the viscosity of the fluid.